Site Investigation

Site Investigation, S.I (or commonly known as Soil Investigation in Malaysia) are crucial in all construction projects. Site Investigation is usually performed by drilling Boreholes into ground to obtain information on the physical properties of soil and rock around a site for the purpose of earthworks and foundation design of the proposed structures. The soil investigation techniques are also applicable for repair of distress to earthworks and structures caused by subsurface conditions.

To obtain information about the soil conditions below the ground, some form of subsurface exploration is required. Methods of observing the soils below the surface, obtaining samples, and determining physical properties of the soils and rocks include test pits, boring and in situ tests.

Test Pits can be carried out by manual hand dug with shovel or machine excavated up to 4.5m deep for the purpose of soil sample collection and observing soil condition. This technique is usually applicable only for low rise developments where it does not involve deep foundation.

For deep soil boring, the most commonly used technique is Rotary Wash Boring, where our drilling rig can bore up to 100m depth, depending on site condition. Disturb and Undisturbed soil samples can be collected by Split Spoon (SPT Sampler), Piston Sampler, Thin wall tube, Mazier, etc. When a rock layer is reached, coring method can be used to core through the rock and collect rock samples.

In situ test which were commonly carried out during soil testing includes Mackintosh Probe Test, Standard Penetration Test (SPT), Vane Shear, Dynamic Cone Penetration (DCP) and Cone Penetration Test (CPT)

All the results and findings obtained from the Site Investigation Works would be presented in Factual Geotechnical Report which consist of Borelog (with Soil Descriptions, In-Situ test result) and also Laboratory Test results.

Here are some detailed description of few typical terms and techniques which is commonly used in Site Investigation works:

Soil Boring (Rotary Wash Method)

Rotary Wash Soil Boring

Rotary Wash Boring is one of the most common method used to drill a borehole during Site Investigation work. Drilling Fluid (Usually water) is used to flush off soils to create borehole in ground with steel casing which is rotated by the Drilling Machine. The purpose of drilling a borehole is to allow for access into deep ground to carry out other in-situ test, sampling and installation of monitoring instrument at designated depth. This method is capable of drilling up to approximately 80-100m depth depending on ground condition.

JKR / Mackintosh Probe Test

JKR / Mackintosh Probe Test is a quick and economical way to estimate the Bearing Capacity of Soil layer by co-relating the cone penetration resistance to the bearing capacity. It can goes up to a maximum depth of 15 m and is recommended only for shallow foundation. This method is not able to collect any soil or rock samples and unable to report on type of soil as well. Its also not suitable for rocky areas.

For more details of JKR/Mackintosh Probe Test, Please refer this page.

Hand Auger

Hand Auger drilling is carried out by using hand held auger which is manually drilled into ground to obtain soil samples. The drilled depth is very limited (usually less than 5m) due to the limitation of human power. This method would only being considered under special circumstances, such as drilling fluid is not permitted, or borehole location is inaccessible to drilling machines, etc. It doesn’t gives any soil resistance value, and also unsuitable in sandy or high water table area, because the open auger hole will tend to collapse.

Trial / Test Pit

A test pit is carried out by excavating the ground to the designated depth (not more than 5m deep) to observe the soil profile underneath and collect bulk samples.

Standard Penetration Test (SPT)

Standard Penetration Test (SPT)

Standard Penetration Test (SPT) is one of the most common field test to determine the driving resistance in soil strata. This method is done in accordance to BS 1377:1990, “Determination of the penetration resistance using a split barrel sampler and a self tripping hammer of approved design”. The result is presented as SPT-N value which indicates blow count per 300mm penetration.

SPT equipment consist of a 63.5kg hammer, hammer fall guide, anvil, automatic hammer release system and a split barrel sampler. The SPT is carried out by repeatedly driving the split barrel sampler into the ground at the desired depth level (usually at 1.5m interval) using the automatic hammer release system that would free fall the 63.5kg hammer with a drop height of 0.76m. Number of blow counts to achieve a penetration of 75mm into ground is recorded. The same procedure is repeated for 6 times for a total of 450mm penetration.

The first 2 layer of 75mm penetration each is considered as seating drive and not counted in reporting the SPT-N value. The total number of blow counts within the final 300mm penetration (separately recorded for every 75mm penetration) would be taken as the SPT-N value.

The Soil samples recovered from the split barrel were preserved as disturbed samples for subsequent testing in laboratory.

Rock & Soil Sampling

Rock & Soil Sampling is one of the most important scope in Site Investigation work. It provides an in-depth understanding on type of the material and its characteristic behavior in substrata.

Soil Samples can be obtained using various techniques depending on soil condition and can be classified into Disturbed (D) or Undisturbed (UD) samples. Disturb samples is usually collected by using SPT split barrel while Undisturbed samples can be extracted using Block Sampler Box, UD Tube, Piston Sampler & Mazier Sampler. The samples collected would be used as specimen in laboratory test later for various classification, strength, consolidation and chemical content test.

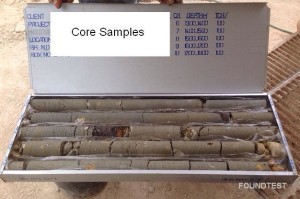

Rock Samples can be extracted from deep ground using Diamond Core Bit with Core Barrel. The Core Recovery Ratio (CRR) and Rock Quality Designation (RQD) would be reported for each core run.

Disturb Soil Sampling

Core Sample

Rock & Cavity Probing

Rock & Cavity Probing is carried out to determine the exact depth of bed rock and existence of cavity. This information is very useful during the piling stage and it could have huge impact on the cost and design of piling foundation, especially when a development is carried out on a limestone area. Cavity Grouting could be carried out for area where cavities is encountered.

Laboratory Test

Geotechnical Laboratory

Being a One Stop Geotechnical Soil Investigation contractor, Foundtest Drilling also provides laboratory testing services as well. All construction materials, soil samples (disturb & undisturbed) and rock samples collected on site can be further tested in our associate labs according to the client or design engineer’s requirement.

| LABORATORY SOIL TESTS | BS1377 : 1990 | |||

| MOISTURE CONTENT | Part 2, Method 3.2 | |||

| ATTERBERG LIMITS ( LL, PL, PI ) | Part 2, Method 4 & 5 | |||

| LINEAR SHRINKAGE LIMITS | Part 2, Method 6.5 | |||

| BULK DENSITY | Part 2, Method 7.2 | |||

| SPECIFIC GRAVITY ( PARTICLE DENSITY ) | Part 2, Method 8 | |||

| PARTICLE SIZE DISTRIBUTION – COARSE GRAINED. | Part 2, Method 9.2 & 9.3 | |||

| PARTICLE SIZE DISTRIBUTION – FINE GRAINED. | Part 2, Method 9.5 | |||

| UNCONFINED COMPRESSION TEST ( UCT ) | Part 7, Method 7.2 | |||

| 38mm diameter, 1 specimen | ||||

| 50mm diameter, 1 specimen | ||||

| 70mm diameter, 1 specimen | ||||

| UU TRIAXIAL COMPRESSION TEST WITHOUT P.W.P. | Part 7, Method 8 | |||

| 38mm diameter | ||||

| 50mm diameter | ||||

| 70mm diameter | ||||

| CU TRIAXIAL COMPRESSION TEST WITH P.W.P. | Part 8, Method 7 | |||

| 38mm diameter | ||||

| 50mm diameter | ||||

| 70mm diameter | ||||

| CD TRIAXIAL COMPRESSION TEST WITH P.W.P. & VOL. | Part 8, Method 8 | |||

| 38mm diameter | ||||

| 50mm diameter | ||||

| 70mm diameter | ||||

| ONE DIMENSIONAL CONSOLIDATION TEST | Part 5, Method 3 | |||

| e vs log pressure, Mv & Cv, t90 graphs | ||||

| e vs log pressure, Mv & Cv, t50 & t90 and c-alpha | ||||

| LABORATORY PERMEABILITY TEST | ||||

| Falling Head Permeameter ( k>E-04 m/s ) | [ KH Head, Vol.2 – 10.7.2 ] | |||

| CHEMICAL TESTS ON SOIL / WATER | ||||

| pH value | Part 3, Method 9 | |||

| Total / soluble sulphate | Part 3, Method 5 | |||

| Chloride content | Part 3, Method 7 | |||

| Organic matter | Part 3, Method 8 | |||

| Total dissolved solids | Part 3, Method 9 | |||

| Salinity Test | Part 3, Method 10 | |||

| DIRECT SHEAR STRENGTH ( 60 x 60mm samples ) | Part 7, Method 4 | |||

| Soaked – Consolidated Drained ( 3 specimen ) | ||||

| ROCK TEST | ||||

| Unconfined compressive strength | [ ASTM D2938-79 ] | |||

| UCT with Young’s Modulus & Poisson’s Ratio | [ ASTM D3148-80 ] | |||

| Point Load Strength | [ Broch, E & Franklin, JA ] | |||

Monitoring: Inclinometer , Standpipe Piezometer

Inclinometer: To monitor horizontal movement of soil layer to prevent any soil erosion and other construction problems. Inclinometer track would be installed in the borehole along the required depth and reading would be taking periodically to ensure the soil stability.

Standpipe Piezometer: To monitor ground water table or water pressure for foundation design or other research purpose.